Refractory knowledge

- Improve the service life of chrome corund

- Application of Lightweight Clay Brick in

- The origin and development of refractory

- The production process of Refractory Bric

- Introduction to the production process of

- How to Bake High Alumina Bricks

- Lightweight fire brick performance

- Physical properties of refractory materia

Hot Products

Applications of Ceramic Fiber Products in the Ethylene Cracking Furnace

A cracking furnace is one of the key equipment in an ethylene plant, in which small alkanes or heavy oil are cracked into ethylene (CH2=CH2), propylene (CH3CH=CH2), carbon four products (C4) and other products and by-products when heated to a certain temperature in the furnace tube.

Since the temperature in the cracking furnace is 1300 ℃ and the temperature of the center of the flame is up to 1350-1380℃, we must have a full understanding of a variety of materials meet the requirements of the application and economical and reasonable material selection.

The traditional lightweight refractory bricks or refractory castables have high thermal conductivity and poor thermal shock resistance, which increases the heat loss of crack furnaces. Ceramic fiber, as a new advanced energy-saving material, has good insulation properties and good resistance to high temperature, thermal shock and mechanical shock. It is easy to install. Those advantages make it the most ideal refractory insulation material.

Compared to traditional refractory materials, ceramic fiber has the following advantages:

(1) High service temperature

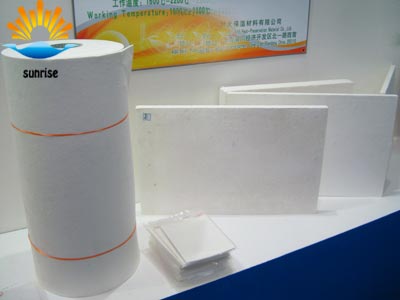

With the development of ceramic fiber production and application technology, ceramic fiber products have achieved serialization and functionalization. They can meet different requirements for service temperature from 600℃ to 1500℃. Morphologically, ceramic fiber has evolved from the traditional cotton, blanket, felt, to module, board, shaped pieces, paper, textile and other secondary processing or deep-processed products. They can fully meet the needs of different industrial furnaces.

(2) Low bulk density

The bulk density of ceramic fiber products is generally 64-320kg/m3, about 1/3 of lightweight bricks and 1/5 of lightweight refractory castables. It can not only save steel, but also simplify the structure.

(3) Low thermal capacity

Ceramic fiber products, compared to refractory bricks and insulation bricks, have low thermal capacity. Since their bulk density is quite different, their thermal capacity is quite different. The thermal capacity of ceramic fiber is about 1/14-1/13 of refractory bricks and 1/7-1/6 of insulation bricks. For cyclical operation cracking furnaces, it can reduce the fuel consumption.

(4) Convenient construction and short circle

Due to the excellent elasticity, it is no need to reserve expansion joints when construction and general workers can be competent for operation.

(5) No preheating and Maintenance

Refractory brick and castable structure require preheating and maintenance. The maintenance period of castables is long, generally 4-7 days. This will reduce the utilization rate of the furnace. If the whole furnace is built with complete ceramic fiber linings, ignoring the limitation of other metal accessories, it can greatly increase the heating rate and improve the utilization rate and reduce energy consumption.

(6) Low thermal conductivity

Ceramic fiber is an assembly of fiber with a diameter 3-5um. There are a lot of voids in it, so its thermal conductivity is low. But at different temperature, the minimum thermal conductivity and the corresponding bulk density increase with the rising of temperature. According to the experience in recent years, the optimal bulk density is 200-220kg/m3.

(7) Good chemical stability and resistance to air scouring

Ceramic fiber can only be corroded by phosphoric acid, hydrofluoric acid and hot soda, but keep stable in other corrosive media.

Next:NONE